Advanced Auto Trends

Advanced Auto Trends

The focus of Advanced Auto Trends, Inc. is to realize financial success and provide employment in the local community for many years to come. AATI is committed to meeting and exceeding our customer’s requirements and expectations through our commitment to the IATF 16949:2016 standard. Furthermore, by concentrating our resources on efficiency in our operations, attention to detail, and through teamwork and a commitment, we will endeavor to continually improve our products and processes, ultimately retaining continual customer satisfaction.

Molded inserts and components, auto and semi-auto high volume molding, sonic welding, cut and sew through plastic, stamping to 400 tons.

Read more

Design partner with customers, design for manufacturing, consult for appropriate material applications.

Read more

Our company builds custom equipment fixtures, including assembly cells, robotic systems, error-proofing devices, and check fixtures.

Read more

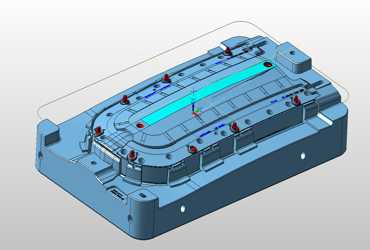

In house tool room, design/build molds, repair / maintain molds and stamping dies, Relationship with international mold build partners.

Read moreWith three production facilities located in south eastern Michigan to serve multiple tier 1 and original equipment suppliers

Complex injection molding from 55 ton to 1100 ton.

AATI has an in house tool room for new mold builds and maintenance to meet complex mold requirements.

Plant 1, Oxford, Mi: Assembly, cut & sew and fixture builds

Plant 2, Oxford, Mi: 55 ton to 230 ton injection molding and tool room

Plant 3, Snover, Mi: 300 ton to 1100 ton injection molding, stamping, tool room and fixture builds